Beta Prime Industry

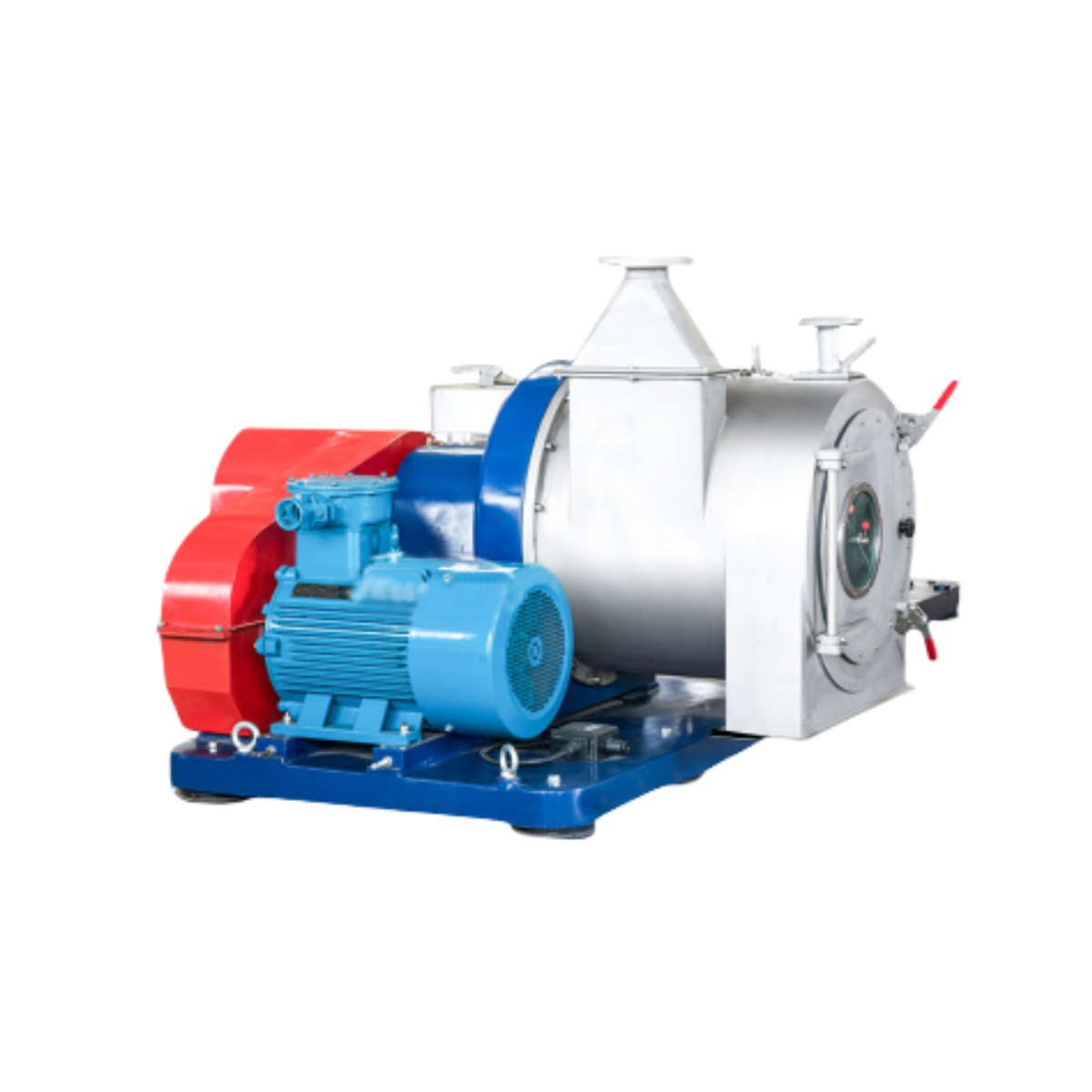

Horizontal Screen Worm Centrifuge

Horizontal Screen Worm Centrifuge

7*24 Online!

sale@betaprimeindustry.com

WA:+86189 8077 6200

TT, Paypal, LC Payment Acceptable.

Contact us to get discounts.

Couldn't load pickup availability

Operational Characteristics:

This machine features low energy consumption, stable performance, and excellent separation efficiency. The processes of feeding, dewatering, washing, and discharging are completed continuously, enhancing production efficiency and automation. It is an optimal solid-liquid separation device.

Working Principle:

The suspension enters the spiral cavity through the feed pipe and is discharged into the drum near the tapered end through the small end of the spiral. Under the influence of centrifugal force, the liquid phase in the slurry is filtered out through the screen placed on the drum wall, while the solid particles are retained inside the drum. Simultaneously, the solid particles move from the small end to the large end of the drum due to the relative differential speed between the spiral and the drum. During this movement, the increasing rotation diameter rapidly enhances the centrifugal force, reducing the moisture content of the solid phase from its initial entry to its discharge, thus achieving automatic and continuous solid-liquid separation.

The centrifuge is equipped with a washing pipe, allowing the filter cake to be washed while being filtered. The thin layer washing of the filter cake ensures effective washing with low washing liquid consumption. Additionally, a steam pipe can be designed on the back of the drum for high-temperature washing of crystallized materials on the drum’s back surface.

The spiral differential system is available in three configurations: cycloid differential, planetary differential, and hydraulic differential, to meet the separation requirements of different materials.

Main Applications:

The Horizontal Screen Worm Centrifuge is widely used in industries such as chemicals, food, salt, mining, and pharmaceuticals. Due to its separation principles and structural characteristics, it is particularly suitable for materials with relatively large particle sizes where particle breakage is not a strict concern. When selecting this centrifuge, material analysis and corresponding tests should be conducted to determine its suitability and separation performance.