Beta Prime Industry

Yeast-Specific Disc Centrifuge-BPIDC470

Yeast-Specific Disc Centrifuge-BPIDC470

7*24 Online!

sale@betaprimeindustry.com

WA:+86189 8077 6200

TT, Paypal, LC Payment Acceptable.

Contact us to get discounts.

Couldn't load pickup availability

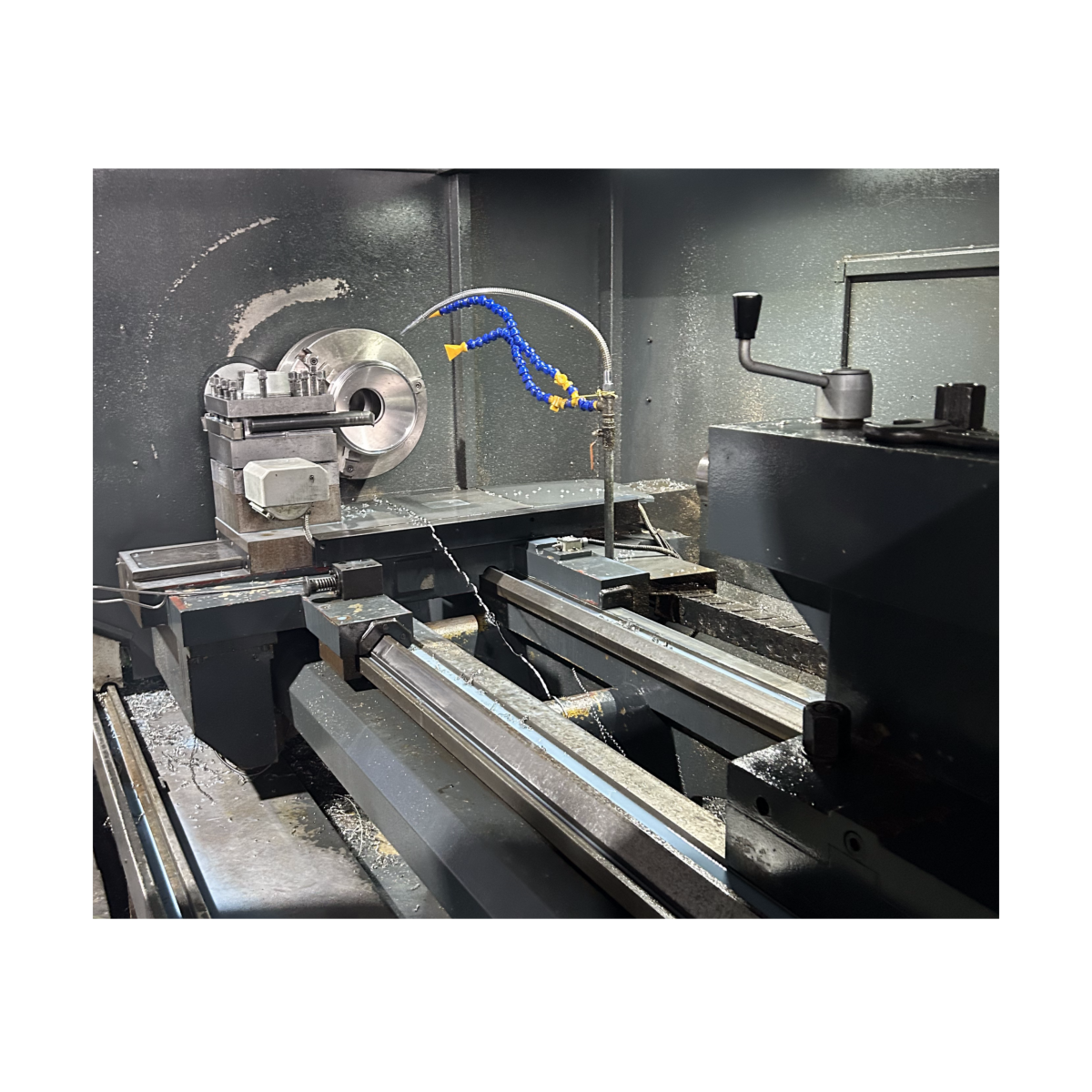

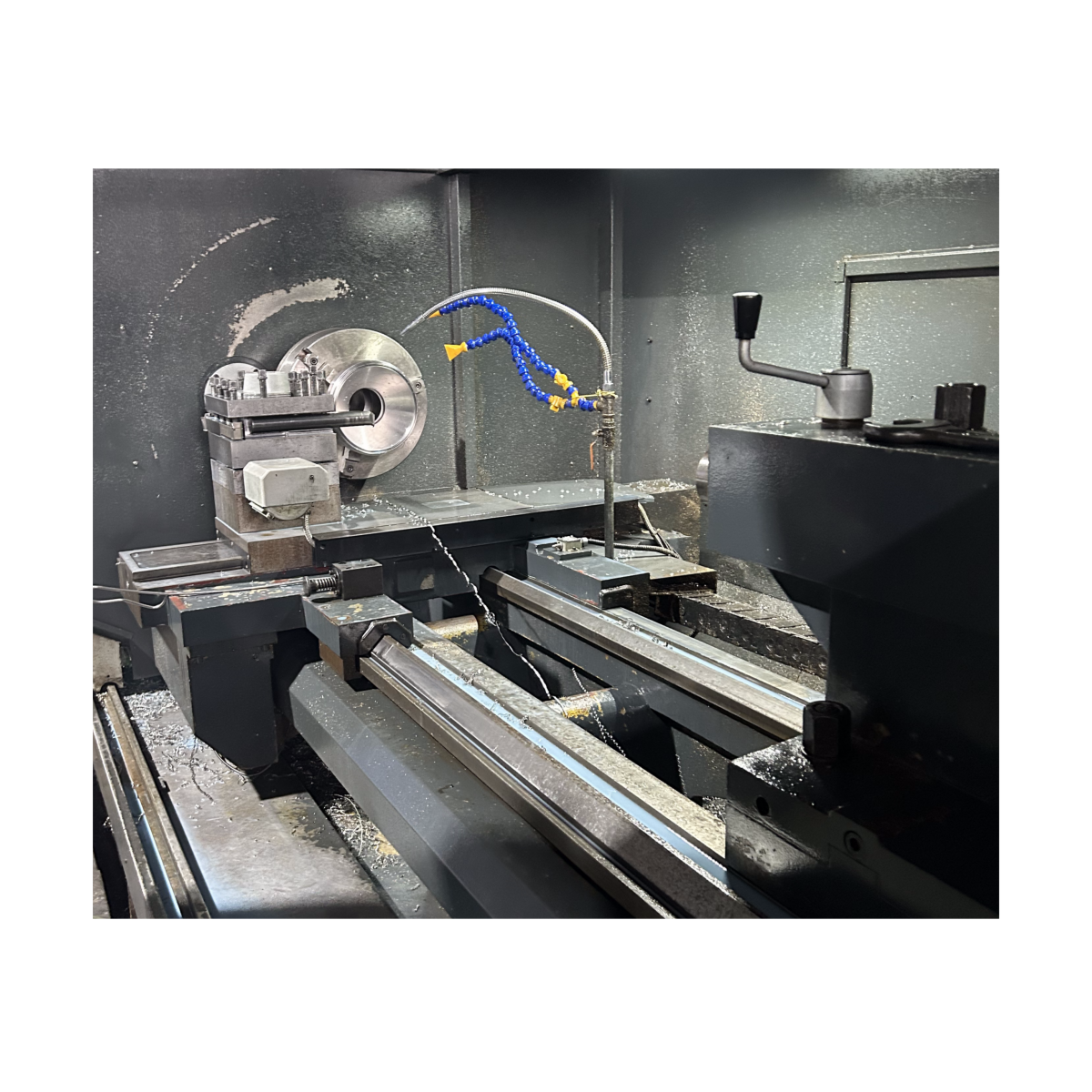

A centrifuge achieves the separation of objects with different densities through the centrifugal force generated by the high-speed rotation of mechanical equipment. The speed of a centrifuge generally reaches several thousand revolutions per minute, or even tens of thousands. High-speed rotation imposes high demands on machinery.

Therefore, disc centrifuges have been widely used in industries such as beverages and dairy products. Initially, they were employed in the beer industry for yeast recovery to reduce alcohol loss. The lower the turbidity requirement, the better. However, cloudy beer requires retaining a certain amount of yeast and small molecular proteins, while also avoiding damage from oxygen exposure. In response to yeast separation technology, Beta Prime Industry has specifically developed this disc centrifuge equipment.

Selection Criteria for Technical Indicators:

The drum in Beta Prime Industry's disc centrifuge is made of 2205 or 2507 materials. Typically, after fermentation, the number of yeast cells in the wine is in the millions per milliliter, with over a hundred million at the bottom, and yeast with good settling properties settling to around several million after prolonged placement. The number of separated yeast cells generally requires to be below one million. Large molecular proteins need to be removed while retaining small molecular proteins. For beer turbidity exceeding 2 EBC, the centrifuge speed needs to be adjustable to meet turbidity requirements. Oxygenation level is a key indicator, with generally no more than 10 ppb of oxygenation during centrifugation to prevent damage to beer quality.

Selection of Slag Discharge Method:

During centrifugation, yeast in the centrifuge needs to be promptly discharged. There are generally two slag discharge methods: timed discharge and automatic discharge. Timed discharge is simple to control but may result in high alcohol loss or high turbidity due to lagging or premature discharge. Automatic discharge requires coordination with a turbidity meter to automatically control based on turbidity, achieving stable turbidity. In the configuration of the centrifuge system, instruments such as turbidity and dissolved oxygen meters are of high value. There may be a significant price difference for fully automatic control. Craft breweries should choose according to their actual needs. If the requirements are not high, manual or semi-automatic options are also viable.

Maintenance:

Beta Prime Industry provides one year of free after-sales service. Therefore, after the installation of the equipment, it should be put into use as soon as possible to realize its inherent value. Moreover, if there are any issues with the equipment, prompt contact can be made for timely improvement.